Services

Welding and sheet metal work

We offer welding and sheet structure service from the beginning to the end. We master different welding methods from MIG welding, robot welding to submergerd arc welding and we take notice of work safety and invest in sustainable work results. Our core competence is producing small and mediumweight frameworks, but heavyweight production is not unknown to us either.

We use the certified ISO 3834-2 quality system for the quality assurance of our welding. We continuously take notice of our welding methods and developing them and the expertise and education of our welders.

We perform oxy-fuel, plasma and laser cutting and CNC stamping and wringing in cooperation with our long-term partners.

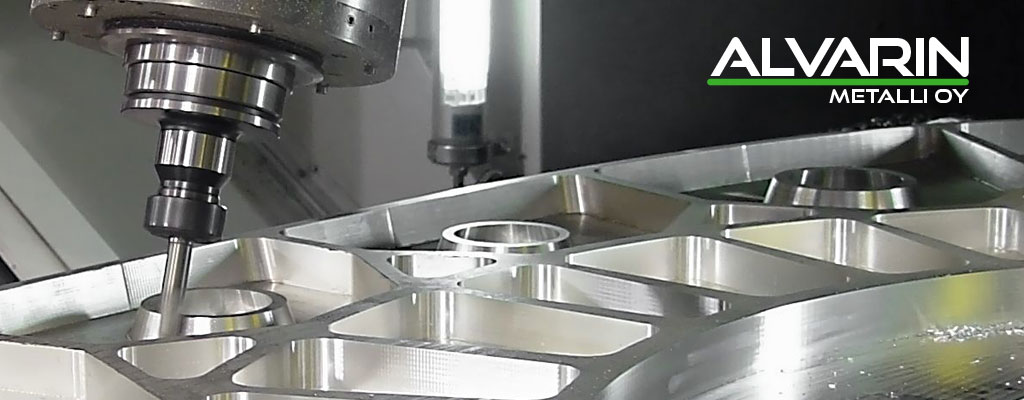

Machining services

In machining we serve our customers comprehensively from small turning parts to challenging big frameworks. We machine welding frame parts produced by ourselves and molding or steel frames delivered by the customer. We broadly machine different materials with expertise from structure steel to aluminiums, stainless steels and special steels.

The modern machine collection and good processing capacity allow challenging machining projects. Our machining capacity is reinforced with a broad and long-term cooperation network.

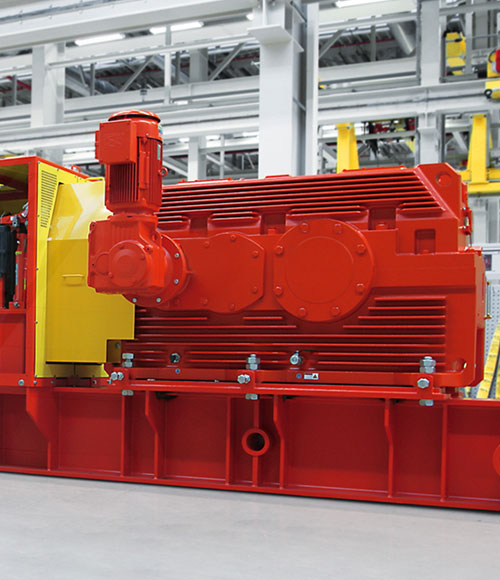

Welded and machined frameworks

We deliver a complete framework or a subsystem welded and machined. We also machine ready parts or moldings already welded by the customer. We also offer frameworks that are only welded.

Blasting and painting

We perform surface finishing mainly in our own paint shop (15m x 10m x 4m) and preparations in our abrasive steel blasting room (18m x 8m x 6m). Our paint shop uses electrostatic wet painting or a regular high pressure paint sprayer. Abrasive steel blasting is used for ensuring the cleanliness of the surface in preparation without the disadvantages of sandblasting. Objects can be steam washed before blasting if needed.

Other surface finishing such as powder painting, galvanization, blackening and phosphatizing is provided by our long-term cooperation partners.

Measurement, calibration

We invest in modern technology and production methods in the manufacturing of demanding products. Pieces and tools are measured using 3D technology. Essential parts of measurement technology include values, units, measurement standards, measurements, processing of results and evaluation of reliability.

During assembly, machine parts must be perfectly compatible. A skilled measurer must verify that the preparations follow the appropriate tolerances and standards.

Assembly

Alvarin Metalli delivers devices or subsystems as complete assemblies or subassemblies to the customer’s own assembly line. We can also deliver assemblies straight to the end customer.

Our assembly takes care of small and big device systems, assembling our own components or the customer’s components into complete products quickly and efficiently.

Assembly is a significant competitive factor especially when the production line has to survive several products of different series as quickly as possible. Assembly and installation jobs can be performed by us either as one-time projects or with a continuous contract, with high quality and certainty. Because of our own component production we guarantee high quality and quick deliveries for the parts.

Direct feedback from assembly to part production also helps us with the quality of the end product and brings savings to expenses.

Total and system deliveries

A product created in the same house from the beginning to the end is often an inexpensive, reliable and quick way for the customer to have machines and devices done. A certain operator can be the best one for the scheduling, expenses and management of the project, which helps the product delivery fit the agreed schedule and minimize reclamations.

Complete and system deliveries are tailored according to the customer’s needs. The customer may participate in the project if they want, but when trying save resources the delivery can be requested with the turnkey approach.

The complete delivery may contain the following factors to form an entirety for the customer’s needs: public authority tasks, project management, design, competitive tendering, steel structuring, electricity work, hydraulics, automatics and earthwork. We utilize our broad and reliable subcontraction network when needed, which allows us to respond to different needs and demands diversely.

With complete subcontraction the customer receives a complete machine, device or device part. We produce the parts, do the purchases, perform the assembly, electricity work and test the products.

Production of replacement parts

We produce replacement parts with the customer’s documentation or possibly from a model. We are able to produce parts with a very short delivery time if needed, and we may also produce most commonly needed parts into our stock.

Product design

Product design is a relevant part of product development. Good design already partially guarantees the functionality and expedience of the product.

We design products independently and together with customers. We also do business with different engineer and design agencies and public authorities. The basis for our design is the customer: the purpose of the product, the desired features, the budget and the time schedule.

We implement design work by subcontractions from a capable and experienced industrial designer. 3D models of the products are drawn with CAD software and the required dimensional drawings are delivered to the customer and to production.

Prototypes and projects

Prototypes and project products are produced in tight cooperation with the customer. Parts may be produced according to the customer’s plans or we may take care of the production from the design on.

We also want to be in tight contact with the customer’s design and bring the required production vision already during the planning stage and in this way help lower the production expenses.