Purchasing and external resource management play a crucial role in the company’s success in an internationally growing trade. For Sandvik, this means optimizing the delivery of goods as well as the entire service chain. Supply chain management focuses on comprehensive know-how, quality and cost-effectiveness, with the purpose of providing added value for the customer.

The cooperation between Alvarin Metalli and Sandvik began already in 2012, when the engineering workshop with the help of an active approach, gained a foothold as a partner with Sandvik. The open dialogue and agreement on operating models between the parties, resulted among other things, in a 9001 quality system certification. Patrick Karhu’s (Sourcing Engineer) job description includes supplier collaboration, quotes and price negotiations for specific sourcing categories. He is actively involved in the development, maintenance and implementation of procurement processes, reporting and procurement systems. “Alvarin Metalli has not been disappointing, we got off to a good start,” Patrick says of his experiences. “We have learned to trust the workshop that is an important supplier of subcontracted parts to Sandvik. It is difficult to guarantee the quality of complicated, welded and machined parts. In large series, working methods can be refined, but in the case of small series, there is no mass work effect. Alvarin Metalli has the ability to undertake challenging work that requires skilled workers,” Patrick concludes.

The NPD project strengthens cooperation

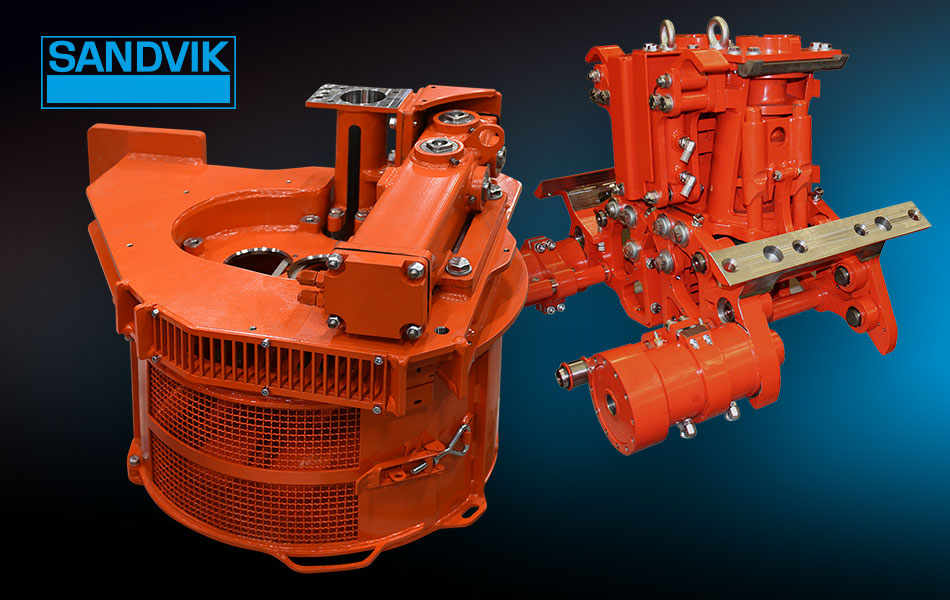

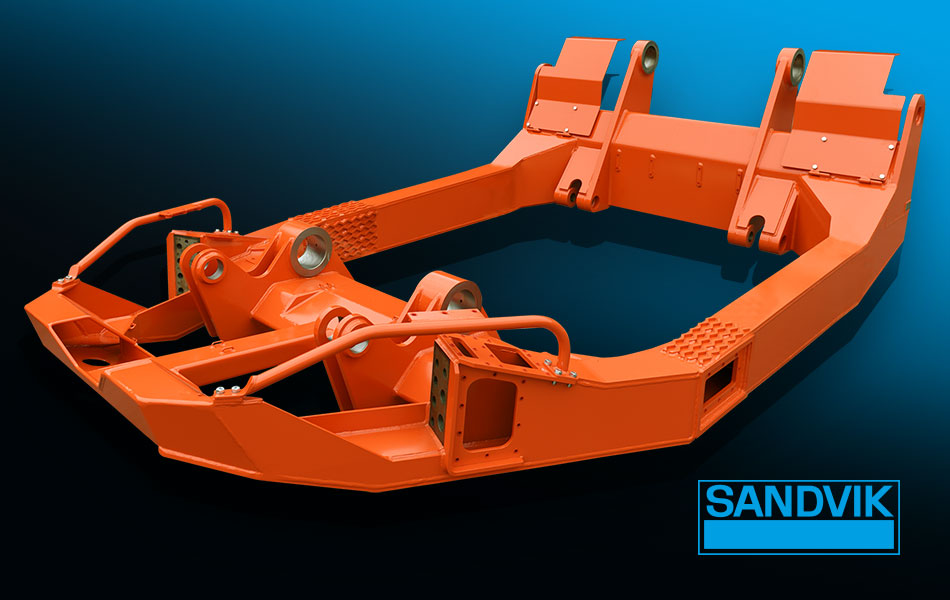

In ten years, the cooperation has increased step by step. Current activities include turn-key machining of large pieces. Sandvik employs Alvarin Metalli a lot, which contributes to keeping the know-how up to date. A challenge for the production department is fluctuating demand and small series, this requires that the subcontractor is flexible and service-oriented. Sandvik has therefore included its partner in an NPD program that manages product development projects from concept to finished product. Alvarin Metalli participates, among other things, in making prototypes of certain parts that require collaboration with designers for optimal assembly and quality. A good procedure identifies the danger points already in the early production stages, especially in the case of non-bulk products. In addition to its traditional subcontracting and contract manufacturing role, the workshop offers Sandvik a service that aims at identifying lower manufacturing costs and better product performance.

Successful communication facilitates purchases

Purchasing plays an important strategic role in today’s companies, it is very important to find good partners who are able to deliver the desired parts, at the right delivery terms. In the role of purchaser, Kaisa Hurske keeps in contact with the workshop on a daily basis. Her job is to make sure Sandvik gets the right parts and components to be able to make the right product at the right time. “The know-how is up-to-date and communication remains active throughout the delivery stages,” Kaisa says about the collaboration with Alvarin Metalli. “I’ve only worked in purchasing for a few years, but both Arttu Alvari and Pauli Yli-Lankoski are experts, whose assistance I can trust.”

“Arttu Alvari is a captivating person, and as a company Alvarin Metalli is flexible and cooperative,” says Riku Santala (SCM). The goal is to increase communication between all players, thereby lowering costs, increasing sales and improving customer service. “As a youthful business leader, Arttu understands commerce and exemplary service supports a partnership that has been refined into collaboration. Alvari’s advantages also include developing production methods and investing in work resources at the workshop.” Riku Santala also emphasizes the importance of trust.

The product is what it is supposed to be, and product knowledge allows for a so called quick purchase, i.e. when the price and delivery are right, there is no need to separately verify each order with the contract supplier. It is to the buyers benefit, that cooperation with the supplier is prompt and easy. Alvarin Metalli manages the production process with flexibility and economically, starting from spare part supply.

Safety, high technology, quality productivity

Occupational safety is an important part of Sandvik’s corporate culture and the same goals are passed on to suppliers. This results in direct savings for both parties, as the risks of accidents at work are minimized and workers’ sickness absences are reduced.

“Sandvik challenges their suppliers with methods and goals for security. It requires long-term work. In several departments, Sandvik has reached a 0 level in accidents leading to absence, which we are very proud of, ”says Juhana Lemmetyinen (SM).

As part of the evolving collaboration, all of Alvarin Metalli’s staff visited Sandvik to see the finished equipment delivered to the end customer. They can take great pride in their professional skills, and their handprint is visible in Sandvik’s advanced end-products. Mutual knowledge and appreciation increase the motivation to produce high quality work for an international demand.

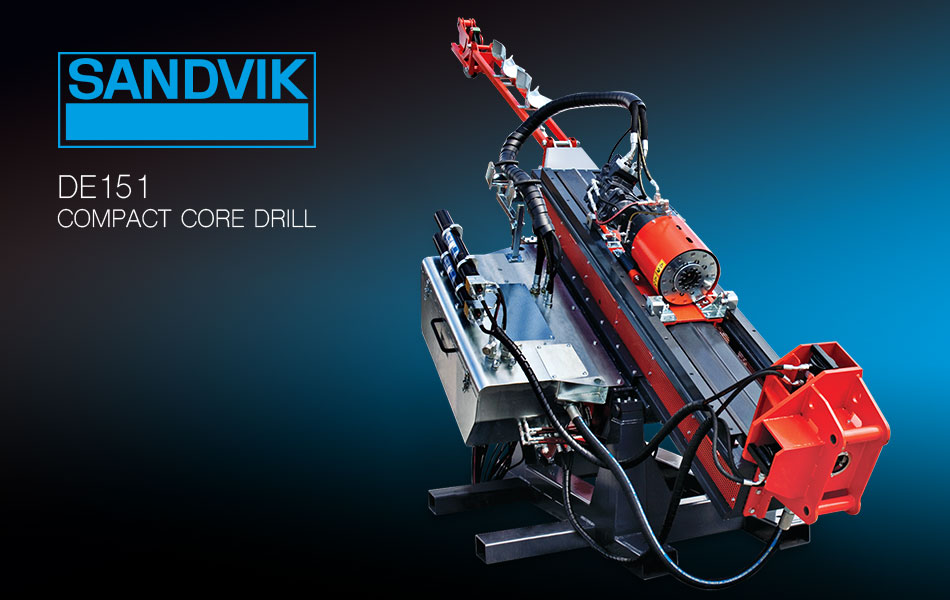

Sandvik’s new generation research equipment focuses on high automation, ergonomics, simpler mobility and improved visibility. With safety in mind, the driver is better protected from hydraulic components without compromising productivity and efficiency.

The Sandvik Group is a world leader in mining and construction equipment, tools and technical solutions. Applications include rock drilling, rock cutting, crushing and screening, loading and transportation, tunneling, quarrying and crushing, and demolition. In 2018, the Group had approximately 42,000 employees in more than 150 countries and had sales of SEK 100 billion.

Discover Sandvik: www.home.sandvik/en/

Sisällöntuotanto: JiPS Oy – Teksti: Raija Sundgrén, kuvitus Jari Sundgrén