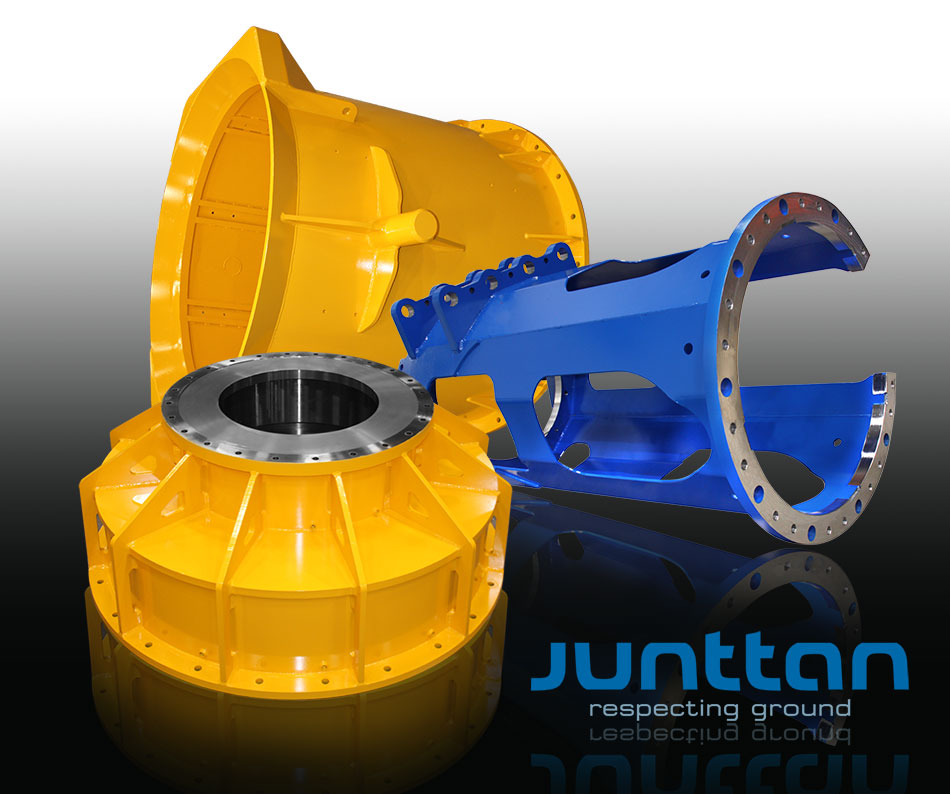

Alvarin Metalli manufactures welded and machined parts, hydraulic pads, impact pads and housings for Junttan. Sales have increased steadily since 2013, when Junttan placed their first order for a 1000 kg drive collar. The product designed in 2007, is still manufactured as the end product typically has a lifespan of up to 30 years. Each year, Junttan produces about 50 piling machines and 20 boulder machines, usually one at a time.

More partnership than supplier relationship

Alvarin Metalli is a significant supplier for Junttan. Collaboration is more of a partnership than just a customer-supplier relationship. As it takes a long time to build an effective relationship and supplier selection is a multi-step process, a selected partner is largely a locked partner.

“It is not profitable to only pick the raisins from a bun and look for a new supplier after a while, it may result in an expensive manoeuvre,” says Purchasing Manager Saku Korhonen. “Sure, we are constantly awake and following the progress of our relationship, but part of a smooth production process includes keeping the agreed rules and practices.”

Partnership is a mutual exchange of information and repetitive work, from testing efforts to normal production. Alvarin Metalli also plays a strong role in the Junttan design and quality department. The creation of a new prototype also requires the workshop to fine-tune details and develop production methods.

The cornerstones of cooperation are highlighted in an emergency

Markku Huotari is responsible for sourcing and purchasing heavy steel structures for Junttan. He keeps in contact with the workshop on a daily basis, and knows how much negotiation, organization, and also improvement suggestions are sometimes required in the manufacturing technology field. “The supplier schedule is the cornerstone of our collaboration. The end product is influenced by the quality of the end-customer’s piling work. For example, soil and product specifications are only made at the last minute before delivery. Therefore, the supplier is required to make quick moves and be flexible to keep the schedule. When the suppliers know the product, they are also able to work proactively with the delivery schedule in mind.

The information flow between Alvarin Metalli and Junttan works well. This is emphasized when delivery is affected by one or another disaster. Surprises sometimes surface, and they surface at Alvarin Metalli too. Thus, flexibility and agility are required from the workshop. “A constant current is sought and 80-90% is achieved, but rapid response is an advantage for Alvarin Metalli in times of emergency. The normal delivery time from blueprint to finished product is about 6-8 weeks, but even demanding products have been successfully finished in just over 2 weeks. However, it is not good if the partnership is built solely on flexibility and the close calls. The integrated mindset is that cooperation should benefit both parties,” says Saku Korhonen.

Cooperation in exceptional circumstances

Alvarin Metalli produces semi-finished products to reserve storage, even if the product recall time is 3 months from order. Again, work anticipation and flexibility are key. This will keep the overall cost at a steady level on both sides. Markku Huotari can also rely on his partner in exceptional circumstances. An example is an emergency where a workpiece got stuck in a machine tool due to machine failure.

Alvari’s reaction to the situation was immediate. During the night, the unfinished piece was removed and sent for machining to Junttan’s own workshop, although Alvari’s own production was in working order the following day. The device was delivered to the customer on time.

Continuous development of cooperation

In addition to daily discussion and status reports, good cooperation requires strict order control and, for example, order confirmations. The purchasing team at Junttan organizes supplier events to generally exchange news and discuss industry prospects, delivery times, capacity, and opportunities offered by new technology.

Alvarin Metalli is constantly investing in technology and their premises to achieve the best possible production process. Thanks to new technology and professionalism, Alvarin Metalli is able to provide Junttan with efficient machining and product quality.

Alvarin Metalli supplies Junttan with welded and machined parts, hydraulic pads, impact pads and housings.

Product Example: Junttan PMx20

- power unit body for impact

- a major component that can withstand high forces

- demanding engineering skills

Brochures:

Pile Driving Rig – PMx20 (.pdf)

Junttan – Hammers brochure (.pdf)

Junttan Oy designs and manufactures hydraulic piling equipment. The Junttan product range includes the world’s leading pile driving machines, multi-purpose and drilling machines, stabilizing machines as well as hydraulic pads, drills and power units. Each construction project has its own characteristics and the soil has a major influence on how piling work is best executed. Junttan piling equipment is made to order and purposed for specific use.

Junttan is the only player in Central Europe in its field and is the European leader in certain working methods. The goal is for the company to further increase its global presence. Junttan’s headquarters, manufacturing and production unit is located in Kuopio, spare parts and after sale operations are based in Hyvinkää. In addition, Junttan has 4 subsidiaries worldwide.

Pile driving is an environmentally friendly method that minimizes the ecological footprint due to minimal hidden effects of the pile processing chain. Rapid piling without the need for soil removal and low need for auxiliary machines contribute to that piling is both cost-effective and environmentally friendly.

A prefabricated, custom-sized pile made of cast concrete, steel or wood is lifted up and installed by striking the top of the pile with a hydraulic ram. The lower end of the pile, or tip, displaces the soil around the pile that is submerged in the ground.

Discover Junttan: www.junttan.com

Content production: JiPS Oy – Text: Raija Sundgrén, illustration by Jari Sundgrén